Ablative:

material that absorbs heat through decomposition process called pyrolysis at or near the exposed surface

Accelerator:

accelerates cure of a resin

Additives:

the term used for a large number of specialist chemicals which are added to resins/compounds to impart specific properties, for example, flame retardancy, and UV resistance

Adhesive:

substance applied to mating surfaces to bond them together by surface attachment. An adhesive can be in liquid, film or paste form.

Aramid:

high-strength, high-stiffness aromatic polyamide fibres

Aspect ratio:

the length/diameter ratio of a fibre

Blister, blistering:

undesirable raised areas in a moulded part caused by local internal pressure, due usually to rapped air, volatile reaction by-products or water entering by osmosis.

Bulk Moulding Compound (BMC):

polyester resin/glass fibre premix, for injection or transfer moulding, also known as dough moulding compound (DMC)

Carbon fibre:

reinforcing fibre known for its light weight, high strength and high stiffness.

Catalyst (also called hardener):

a chemical compound (usually an organic peroxide) which initiates polymerisation of a resin

Chlorinated paraffins:

flame-retardant additives for polyester resins

Chopped strands:

short strands cut from continuous filament strands of reinforcing fibre, not held together by any means

Coefficient of thermal expansion:

a material’s fractional change in length corresponding to for a given unit change in temperature

Composite: a material made up of resin and reinforcement (usually fibre)

Compression strength:

the crushing load at failure of a material, divided by cross-sectional area of the specimen

Contact moulding:

moulding of fibre-reinforced resins without application of external pressure

Core:

in sandwich construction, the central component to which inner and outer skins are attached. Foam, honeycomb and wood are all commonly used core materials.

Corrosion resistance:

the ability of a material to withstand contact with ambient natural factors without degradation or change in properties. For composites, corrosion can cause crazing.

Coupling agent:

a substance, which promotes or establishes a stronger bond at the resin matrix/reinforcement interface

Cracking:

actual separation of moulded material, visible on opposite surfaces of a part ad extending through the thickness (fracture)

Crazing:

fine cracks, which may extend in a network on or under the surface of a moulded part

Cure:

the process of hardening of a thermosetting resin (by cross-linking of the molecular structure), under the influence of heat

Curing agents:

chemical compounds used to cure thermosetting resins

Curing time:

the time taken for a resin to cure to its full extent

Delamination:

splitting, physical separation or loss of bond along the plane of layers of a laminated material

Direct roving:

roving produced by winding a large and determined number of filaments direct from a bushing

Dough moulding compound (DMC):

polyester/resin fibre premix, for injection or transfer moulding, also known as bulk moulding compound (BMC)

Fibre:

a unit of matter of relatively short length, characterised by a high ratio of length to thickness or diameter Filament:

a single textile element of small diameter and very long length considered as continuous

Filler:

material (usually low cost) added to a resin to extend it, or give special properties

Finishing:

application of coupling agent to textile reinforcements to improve the fibre/resin bond

Flexural strength:

the strength of a material in bending expressed as the stress if a bent test sample at the instant of failure.

Flow:

the movement of a resinous material, thermosetting or thermoplastic, under pressure, to fill all parts of a closed mould

Fracture:

cracks, crazing or delamination resulting from physical damage.

Gate:

the opening through which a moulding compound is injected into a closed mould; the size, geometry and positioning of the gate can strongly influence properties of the finished moulding

Gel:

the state of a resin, which has set to a jelly-like consistency

Gelcoat:

a thin layer of unreinforced resin on the outer surface of a reinforced resin moulding; it hides the fibre pattern of the reinforcement, protects the resin/reinforcement bond, gives smooth external finish and can also provide special properties; it is usually pigmented

Glass fibre:

reinforcing fibre made by drawing molten glass through bushings. The predominant reinforcement for polymer composites, it is known for its good strength, processability and low cost.

Hardener:

see catalyst

HET acid anhydride:

saturated dicarboxylic acid anhydride, containing chlorine

Honeycomb:

light weight cellular structure made from either metallic sheet materials or non-metallic materials and formed into hexagonal nested cells, similar in appearance to the cross-section of a beehive

Hybrid:

a resin or reinforcement made from two or more different polymers or reinforcement materials

Impact strength:

a material’s ability to withstand shock loading as measured by fracturing a specimen

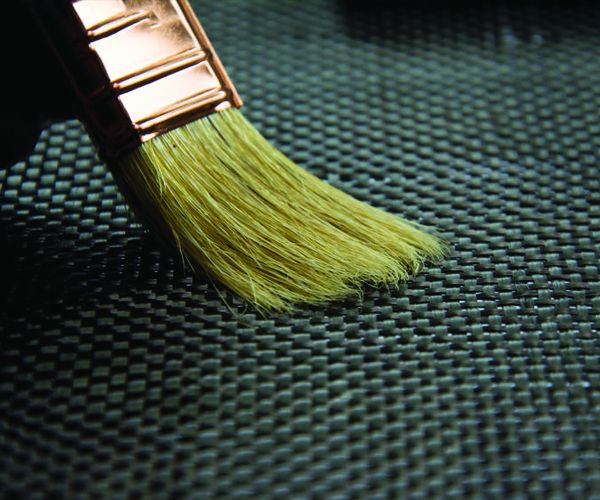

Impregnation:

saturation of reinforcement with liquid resin

In-mould coating (IMC):

a process used with SMC (and recently developed also for thermoplastics) in which a liquid/melt coating layer is applied to the exterior of a moulding while still in the mould, as part of the moulding cycle

Interface:

the contact area between reinforcement and resin

Laminate:

the structure resulting from bonding multiple plies of reinforcing fibre or fabric

Lay-up:

a resin-impregnated reinforcement in the mould, prior to polymerisation

Mat:

a widely used sheet-type reinforcement made up of filaments, staple fibres or strands, cut or uncut, oriented or random, lightly bonded together

Monomer:

a compound containing a reactive double bond, capable of polymerising

Polyester:

usual term for an unsaturated polyester resin

Polymer:

a long-chain molecule, consisting of many repeat units

Porosity:

numerous air pockets or voids in a moulded product

Post-cure:

application of external heat to bring a resin to a stable state of cure in the shortest possible time

Preform:

reinforcement pre-shaped to the general geometry of the intended moulded part; it is used on more complex and deep-draw mouldings, to optimise distribution and orientation of fibres

Premix:

a moulding compound prepared prior to, and apart from, the moulding operation, containing all components necessary for moulding

Prepreg:

a factory-made combination of reactive resins and reinforcing fibres, plus other necessary additive chemicals, ready to be moulded

Reactive resins:

liquid resins which can be cured by catalysts and hardeners to form solid materials

Release agent:

a substance which prevents a moulding from sticking to the mould surface; it may be a chemical compound or a solid material such as a cellulose or plastics film

Reinforcement:

key element added to resin (matrix) to provide the required properties; ranges from short fibres and continuous fibres through complex textile forms

Resin:

polymer with indefinite and often high molecular weight and a softening or melting range that exhibits a tendency to flow when subjected to stress. As composite matrices, resins bind together reinforcement fibres

Resin transfer moulding (RTM):

a moulding process in which catalysed resin is injected into a closed mould already containing the pre-formed reinforcement

Roving:

endless glass fibre bundles; a collection of parallel strands (assembled roving) or parallel filaments (direct roving) assembled without intentional twist

Sandwich structure:

composite composed of lightweight core material to which two relatively thin, dense, high strength, functional or decorative skins are adhered

Sheet moulding compound (SMC):

a flat pre-preg material, comprising thickened resin, glass fibre and fillers, covered on both sides with polyethylene or nylon film, ready for press-moulding

Size:

a coating applied to glass fibres or filaments during manufacture, to improve handling and protect from abrasion

Strand:

an assembly of parallel filaments simultaneously produced and lightly bonded

Thermoplastic:

a plastic, which softens each time it is heated

Thermoset:

a plastic which flows and then sets permanently on first heating, as s result of setting up a three-dimensional cross-linked molecular structure, and subsequently will not soften or dissolve

Thick moulding compound (TMC):

a compound similar to BMC, but continuously produced in sheet form with a thickness of 25mm or more

Void:

a pocket of gas or air trapped in a laminate or moulding

Wet-out:

complete wetting/saturation of a fibrous surface with a liquid resin

ACM:

advanced composite material

AFRP:

aramid fibre reinforced polymer

BMC:

bulk moulding compound

CFRP:

carbon fibre reinforced polymer

DMC:

dough moulding compound

GFRP:

glass fibre reinforced polymer

FRP:

fibre reinforced polymer

SMC:

sheet moulding compound

TMC:

thick moulding compound